5S Practices

- We understand the challenges of bringing a product to market quickly. C4ISR Cables has the quick turn, rapid prototyping capability required to assist in drawing notes defined, test requirements to ensure your product is ready for implementation.

- C4ISR Cables knowledge of materials and key processes to ensure your product meets all the environmental conditions your product encounters.

- All these variables defined up front with a goal of no Revision changes to save time and cost to get your product to market quickly and aesthetically appealing to your end customer.

- ERP-MRP system, manage by Project, Full lot, serial and revision control, Real time tracking of costs and production status of all WIP, Planning module, full document control, quality tracking, labor tracking and cost controls.

- LEAN 5S workstations.

- Inline assembly testing to prevent rework.

- Paperless work instructions with high content of pictures to IPC class 3.

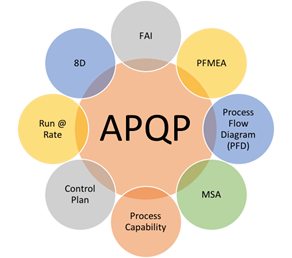

- AS9102 FAI software for automating the process.

- RFQ engineering review for smooth transition to purchase order acceptance.

- RFQ complete tooling analysis for correct tooling for the volume with delivery/cost review.

- Final Electrical test is automated with mates.

- Packaging includes automatic bagging with proper marking of each bag.